Motors

2 or 4 pole, IE 3* high efficiency, three-phase 230/400V 50Hz up to motor size 132 and 400/690V 50Hz for higher motors. IP55, Class F protection.

* From 0,75kW, motor can be IE 2 and controlled by VSD.

On request

• Manufactured from different materials.

• 2-speed motors.

• 60 Hz versions.

• Painted in different RAL colour.

• Fan with no supporting stand (Motor-Flange, Arrangement 5), up to motor size 160.

• High-temperature versions (up to 150ºC) (B versions: with cooling impeller).

• ARRANGEMENT 8: with joint flexible coupling.

• Inspection door, draining, weather seal on scroll and shaft access.

• Welded casing.

• Thermal insulation lagging.

On request, explosion proof versions in accordance with ATEX directive for three phase models:

Ambient temperature -20°C to +60°C, ambient pressure (abs.) 0,8 bar to 1,1 bar according to EN 14986.

• Gas:

2G IIB T2-T3-T4, Motor Exd IIB or ExeII

2G IIB T2-T3-T4, Motor Exd IIB or ExeII

2G IIB+H2 T2-T3-T4, Motor ExdIIc

2G IIB+H2 T2-T3-T4, Motor ExdIIc

3G IIB T2-T3-T4, Motor ExnA (only for 3G zone)

3G IIB T2-T3-T4, Motor ExnA (only for 3G zone)

3G IIB+H2 T2-T3-T4, Motor ExnA (only for 3G zone)

3G IIB+H2 T2-T3-T4, Motor ExnA (only for 3G zone)

• Non-conductive dust

2D IIIB T125°C-T135°C-T195°C-T295°C

2D IIIB T125°C-T135°C-T195°C-T295°C

3D IIIB T125°C-T135°C-T195°C-T295°C

3D IIIB T125°C-T135°C-T195°C-T295°C

• Conductive dust (compulsory IP 65 motor):

2D IIIC T125°C-T135°C-T195°C-T295°C

2D IIIC T125°C-T135°C-T195°C-T295°C

3D IIIC T125°C-T135°C-T195°C-T295°C

3D IIIC T125°C-T135°C-T195°C-T295°C

-

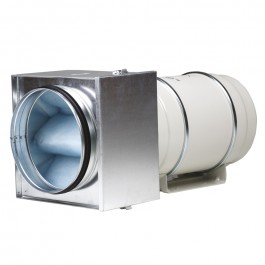

Forward curved impeller for material transport

Reviews

There are no reviews yet.