Fermenter – Bioreactor

High quality and innovative lab scale fermentor and bench top bioreactor at a reasonably low cost. Through innovation to quality, new concepts to increase productivity in laboratory fermentation and cell cultures experiments:

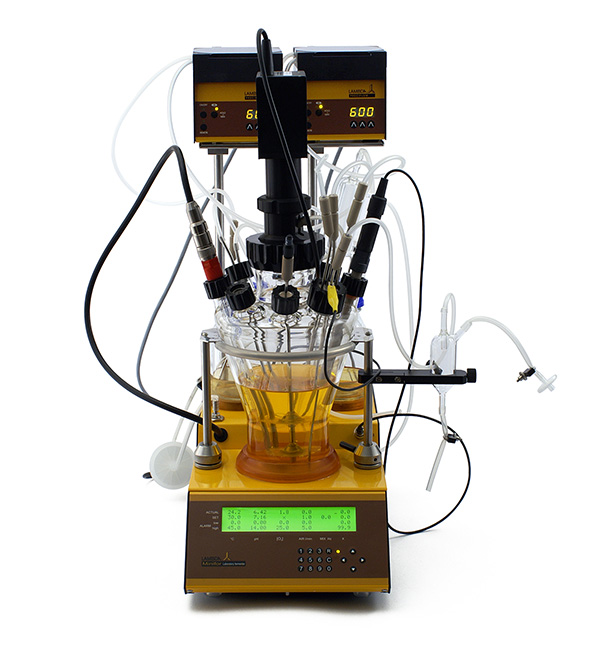

MINIFOR laboratory fermentor and bioreactor

The LAMBDA MINIFOR bench-top autoclavable laboratory fermenter and bioreactor was developed as a result of the need to construct a small laboratory fermentor for working volume ranges from 35 ml to over 6 liters.

Based on long personal practical experience in fermentation and cell culture, a high quality fermentor-bioreactor which is easy to use and with the capacity to measure and control all the important parametersof the biological culture, has been created (which required new ideas and many innovations).

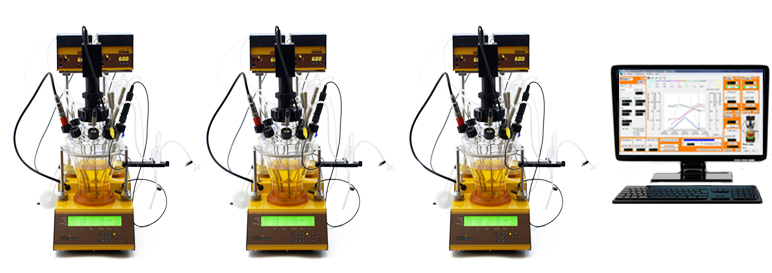

Smallest footprint for parallel experiments

The fermentor had to take up minimum space on the bench, but with good access to all parts. Several fermentors should, when placed side by side, be suitable for the optimization of growth parameters of the culture or optimization of bio-transformations, etc. (highly suitable for parallel running experiments).

The space requirement of the MINIFOR fermentor-bioreactor with working vessel and the control unit is: 22 cm x 38 cm x 40 cm (W x H x D).

Bioreactor operation, remote control and data acquisition

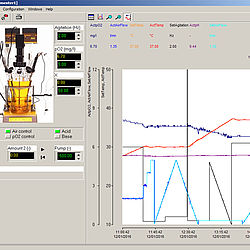

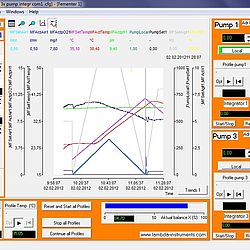

LAMBDA MINIFOR fermentor and bioreactor can be fully controlled and operated from the front panel. All parameters can be immediately seen without scrolling and set values as well as high and low alarms of each parameter can be adjusted on the front panel.

Several MINIFOR units can be connected to one PC and the optional fermentation software SIAM or FNet, allows remote control and data processing.

For connecting multiple MINIFOR fermenter-bioreactor units to the PC, no additional software licenses needed.

Innovations in MINIFOR fermentor-bioreactor for excellent price to performance ratio

To keep the cost of the MINIFOR fermentor-bioreactor low, without compromising quality, several new ideas and innovations have been introduced:

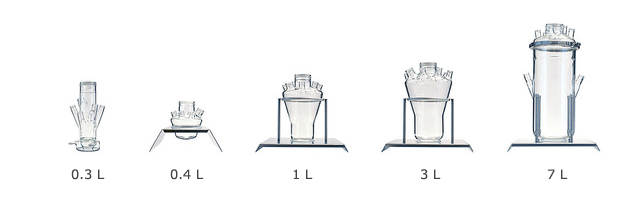

MINIFOR lab scale fermentor-bioreactor vessel volume range

Instead of a fermentor flask with a stainless steel head plates, which is expensive, LAMBDA MINIFOR fermentor and bioreactor use whole autoclavable glass vessels (0.3 L, 0.4 L, 1 L, 3 L and 7 L) with threaded fittings.

The bioreactor vessels have been used in fermentation & cell culture for years and are proved to maintain perfect sterility.

Thanks to the LAMBDA easy sterility concept, the MINIFOR fermenter-bioreactor is set-up in shortest possible time!

Novel non-rotational agitation

Instead of a traditional propeller agitator, which requires an expensive motor and magnetic coupling, LAMBDA introduced a new up-and-down agitation in the bench-top fermenter and bioreactor.

A motor together with an inexpensive membrane perfectly assure sterility and produce an efficient mixingwithout formation of a vortex (no baffles needed). At the same time, this up and down mixing is gentler on cells and produces less foam.

Novel biomimicking “fish-tail” stirring discs together with the up and down agitation offers maximum mixing efficiency without cutting edges.

Precise temperature regulation with IR heating

The culture vessel is heated by heat radiation produced in a parabolic radiator with a gold reflector placed under the fermentation vessel. The heat is absorbed gently by the culture similarly to the sun heating water.

No overheating of the culture at any volume and expensive double-wall vessels with thermostatic baths & heating blankets are completely eliminated.

At the same time, tubing and cables disappear making the lab-scale fermentor less complex.

Regulation of aeration and DO by thermal MASSFLOW gas flow meter

Even the basic kit of MINIFOR lab fermentor-bioreactor is equipped with a thermal MASSFLOW gas flow controller for aeration and regulation of dissolved oxygen.

MASSFLOW with proprietary precise and proportional needle valve allows to automatically control the concentration of dissolved oxygen (DO) by the flow rate variation and not merely by the variation in the stirring speed.

We think that DO should be controlled at any stirrer speed! Or should one tolerate bad agitation at low DO values?

Ergonomic and easy handling

As far as possible, expensive pieces of equipment have been replaced by new high performance plastics.

By using modern microprocessors, it has been possible to place all the electronics in the front part of the instrument. This makes the fermentor unbelievably compact and eliminates the casing tower.

Despite its small size, six parameters are measured and controlled in the basic configuration of the MINIFOR.

Technical Specification

Power: Universal power supply for mains 100-245 V AC/50-60Hz, 560W, CE conform

Dimensions: 22 x 40 x 38 cm (W x D x H)

Display: LCD 4 x 40 digits with backlight illumination

Fermentor vessel: Pyrex glass with 6 to 8 side necks; 0.3, 0.4, 1, 3, 7 liter vessels

Temperature control: High efficiency 150 W infrared (IR) radiation heat source with gilded parabolic reflector

Regulation: from 5°C over RT to 70°C

Measurement: from 0 to 99.9°C in 0.1°C steps

Precision: +/- 0.2°C (0 to 60°C)

Sensor: Pt 100 incorporated in the glass electrode of the pH probe

pH control: sterilisable pH electrode pH 0-14 with automatic temperature correction, two-point semiautomatic calibration and Variopin connector

Resolution: 0.01 pH unit

Precision: +/- 0.02 pH unit

pO2 control: sterilisable Clark type oxygen sensor with fast response, automatic temperature correction, two-point semiautomatic calibration, dissolved oxygen (DO) control through regulation of the airflow rate

Range: 0 to 25 mg oxygen/ l, in 0.1 mg/l steps

Air flow: 0 to 5 l/min in 0.01 l/min steps, measured by precise mass flow meter, linearity +/- 3%, reproducibility +/- 0.5%

Control: proportional valve controlled by microprocessor

For supplied air pressure: 0.05 – 0.2 MPa (0.5 – 2 atm)

Agitation: 50 W Vibromixer 0 to 20 Hz (0 to 1200 rpm) in 0.1 Hz steps (6 rpm) with 1 or more stirring discs; Sterility similar to magnetic coupling

Selectable parameter ‘X’: an additional parameter can be controlled by the instrument (foaming control, weight (for continuous cultures), pCO2, redox potential, conductivity, optical density, etc.); with standard 0-10V or 0-20mA output

Ports / side necks: One large quadruple sampling or additions port with four needles with LAMBDA PEEK double-seal connections, used for sampling, inoculation, antifoam, feeds, harvest, addition of correction solutions etc., additional double ports are available.

Pumps: up to 4 independent pumps (PRECIFLOW, MULTIFLOW, HIFLOW or MAXIFLOW) with speed variation from 0 to 100 % can be used with MINIFOR lab fermenter-bioreactor

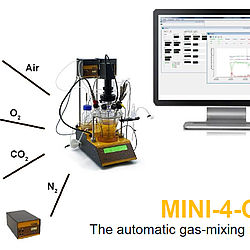

Gas flow control: In addition to pumps, several electronic flow controllers with flow rate ranges of 0-5 l/min (MASSFLOW 5000) or 0-500 ml/min (MASSFLOW 500) can be used for the controlled addition of gases (e.g. N2, O2, air, CO2) in cell cultures; freely configurable gas station module

Working temperature: 0 – 40 °C

Working humidity: 0 – 90 % RH, not condensing

Weight: 7.5 kg

PC control: complete PC control and data processing using the fermentation software FNet (for up to 6 MINIFOR fermenters) or SIAM (for an even higher number of instruments)

Documentation

- EN – LAMBDA MINIFOR Laboratory Fermenter-Bioreactor LEAFLET (pdf)

- EN – 20 innovations of LAMBDA MINIFOR laboratory-scale bioreactors — Overview and Benefits (pdf)

- EN – LAMBDA MINIFOR laboratory fermenter and bench-top bioreactor at universities and highschools (pdf)

- EN – Operation manual: MINIFOR lab fermentor-bioreactor (pdf)

- EN – Infographics: Overview of innovations in MINIFOR lab fermenter and bioreactor (pdf)

- EN – Quick overview of MINIFOR bioreactor vessels with connections, probes & tubing lines (pdf)

- EN – Peltier electronic cooling loop for Minifor fermentor (pdf)

- EN – PUMP-FLOW INTEGRATOR replaces the need for optical density measurements in fermenters and bioreactors (pdf)

- EN – REDOX potential measurement for MINIFOR laboratory fermentor (pdf)

- EN – MINI-4-GAS, the automatic gas mixing module (pdf)

- EN – How to compare the cost and real value of a laboratory fermentor? (pdf)

- EN – Solitary teamplayer in parallel processes – LAMBDA MINIFOR laboratory fermenter and bioreactor (pdf)

- DE – UNI _ LAMBDA MINIFOR Laborfermenter und Tischbioreaktor an Hochschulen (pdf)

- DE – Broschüre _ MINIFOR Laborfermenter Bioreaktor (pdf)

- DE – Parallelreaktor _ LAMBDA MINIFOR Laborfermenter Bioreaktor der Einzelgänger im Parallelsystem (pdf)

- DE – Bedienungsanleitung _ LAMBDA MINIFOR Labor-Tischfermenter und Bioreaktor (pdf)

- DE – Montageanleitung _ Kurzübersicht der Bioreaktorgefässe LAMBDA MINIFOR mit Anschlüssen, Sonden und Schlauchlinien (pdf)

- DE – LAMBDA MINIFOR Laborfermenter und Bioreaktor – Innovationsuebersicht und Vorteile (pdf)

- FR – MINIFOR – fermenteur de laboratoire (pdf)

- FR – Comment comparer le coût d’un fermenteur ou bioréacteur avec sa valeur réelle ? (pdf)

- FR – Le fermenteur et bioréacteur de laboratoire MINIFOR: Le joueur solitaire dans l’équipe des procédés en parallèle (pdf)

- FR – LAMBDA MINIFOR fermenteur de laboratoire-bioréacteur de paillasse et son utilisation dans les écoles et universités (pdf)

- FR – LAMBDA MINIFOR fermenteur / bioreacteur – Resume des innovations et avantages (pdf)

- ES – ¿Cómo comparar el coste y el valor real de un fermentador y biorreactor de laboratorio? (pdf)

- ES – Fermentador y biorreactor LAMBDA MINIFOR: El solitario en procesos paralelos (pdf)

- ES – MINIFOR – fermentador de laboratorio (pdf)

- ES – Fermentador-biorreactor de laboratorio LAMBDA MINIFOR para las escuelas y universidades (pdf)

- ES – LAMBDA MINIFOR Biorreactor-fermentador de laboratorio – resumen de innovaciones y ventajas (pdf)

- ES – Manual de operaciones – LAMBDA MINIFOR Fermentador-Biorreactor de Laboratorio (pdf)

- CZ – MINIFOR – laboratorní fermentor (pdf)

- RU – Лабораторный ферменторбиореактор ЛАМБДА МИНИФОР (pdf)

Accessories

Scale module for continuous cultures Show detail

Scale module for continuous cultures Show detail REDOX potential measurement [mV] Show detail

REDOX potential measurement [mV] Show detail MINI-4-GAS Automatic gas-mix Show detail

MINI-4-GAS Automatic gas-mix Show detail Automatic antifoam control Show detail

Automatic antifoam control Show detail FNet – Fermentor Control Software Show detail

FNet – Fermentor Control Software Show detail SIAM industrial fermentation software Show detail

SIAM industrial fermentation software Show detail MINI-4-GAS software module Show detail

MINI-4-GAS software module Show detail OXYMETER O2 concentration measurement (0-25%) Show detail

OXYMETER O2 concentration measurement (0-25%) Show detail CARBOMETER CO2 concentration measurement (0-100%) Show detail

CARBOMETER CO2 concentration measurement (0-100%) Show detail METHAMETER CH4 concentration measurement (0-100%) Show detail

METHAMETER CH4 concentration measurement (0-100%) Show detail

Reviews

There are no reviews yet.