The triaxial test brings the sample back to its site conditions through the varius steps characterizing the triaxial test (saturation, consolidation) and measure the material resistance to shearing and the connections between stress and strain.

During the standard triaxial test the sample is die-cut or reconstructed in a cylindrical shape, wrapped by an impermeable membrane, laterally confined by hydraulic pressure inside a cell and finally subjected to an axial load which generates the sample breaking.

Various standard triaxial systems, from teaching purposes to advanced laboratory needs, are available complete with dial gauges, dynamometric rings and data acquisition systems for the upgrading.

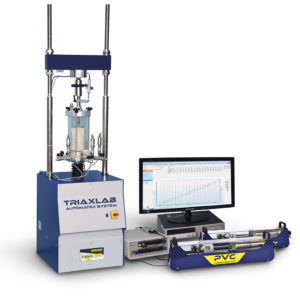

The Automatic Static and Dynamic triaxial machines complete the range, equipped with control units and first level software which can be completely programmable and controllable remotely.

-

Triaxial load frame 50kN

-

TRIAXLAB – Automatic triaxial system

-

Cyclic triaxlab automated system

-

Triaxial load frame 50kN

Reviews

There are no reviews yet.